Week 7

This week I had to put the piston on the back burner, as I needed to wait for the O-rings to arrive. This meant that I was able to focus on something else for a little bit. I started assembling the battery holder which turned out to be a lot more difficult that I expected.

The Formlabs Form 3+ resin printers that the shop has are bullet proof about 97% of the time, however that 3% of the time they are very very frustrating to work with and fix. The first issue that I had was that sometimes when it would print it would make this awful noise, like it was draging on something, causing us to stop the print in fear of it breaking the machine. I finally got a few prints to work, however the print layout was sub optimal, in the sense that one of the very critical sides was blown out and didn’t look good. I tried to remidy this on the next print by washing it sideways so that the left over resin would be washed off and not cure onto the part. This helped enough, and I am currently trying to epoxy the battery clips onto it. I am still not entirely sure what the problem with the printer is, but whatever it is, it is very frustrating.

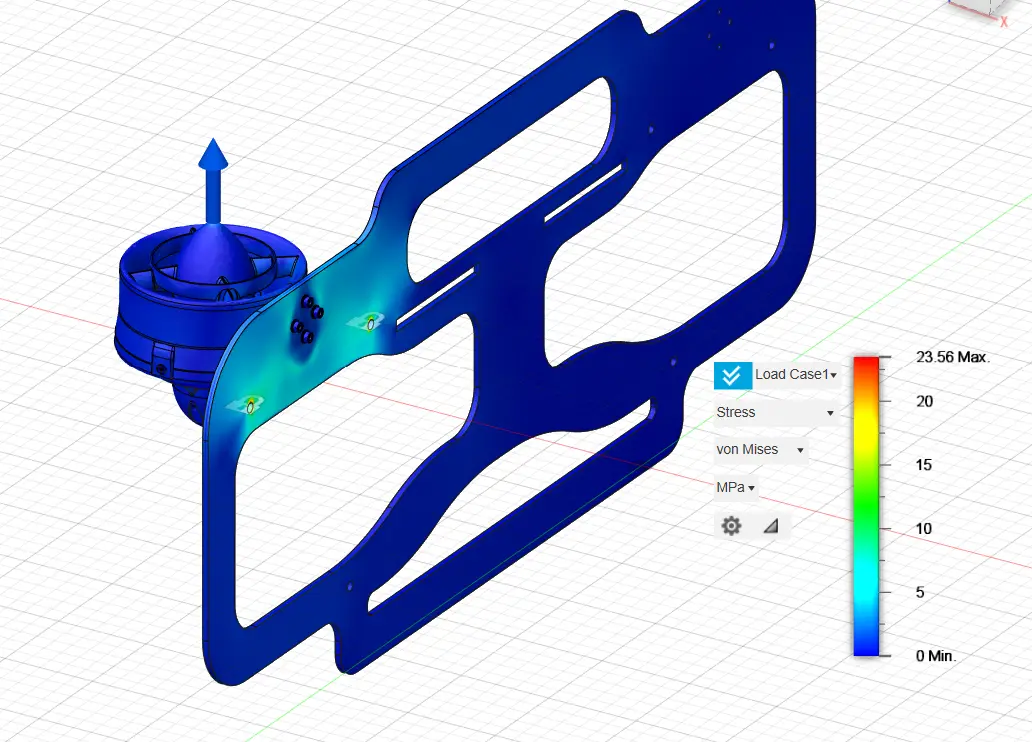

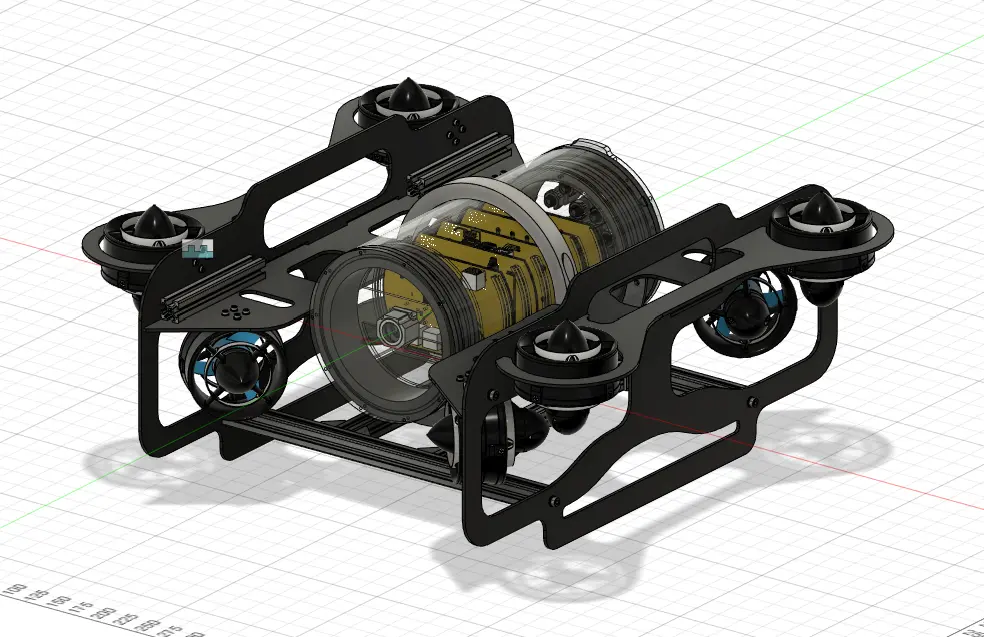

During the week I did many resin prints, which take lots of time, thus I had a lot of down time. I then took a look at the new JONA ROV (the name of our new ROV) CAD model. In there I noticed that the motors are mounted on a long 1/8th inch sheet alluminum and thought that might be a bit precarious and might induce flexing which, wouldn’t be advantageous. I then decided to run a simulation on the model using fusions static stress simulation tool. This was new to me as I had never gotten one of these to work properly. When I got the results back initally it was quite concerning as it displayed the motor mount very bent, but then I quickly realized it was overexagerating the results, and it was totally fine.

On the topic of simulations, I was quite disapointed that fusion didn’t have built in CFD (Computational Fluid Dynamics). This is an area of simulation where you can study how well an object interacts with fluids, such as water and air. This is commonly used in valves, and the aviation, and racing industries. I then became much more invested in this than I probably should be and decided to find how bad this design is actually in terms of drag coeficient. Just a disclaimer here, the design didn’t have any thought of hydrodynamics put into it, as it will hardly move around at high speeds in the competition, thus we prioritized more manuverability over top speed. This being said this isn’t just a waste of time, as a video I watched brought up a very good point, where the rov should still be able to resist ocean currents and be able to manuver. Using my educational Autodesk account I was able to get access to the Autodesk CFD Ultimate software, which I haven’t been able to get working yet, but I anticipate much more time waiting for prints to finish, so I will have plenty of time. Additionally this CFD report, would look very good in the techinical report, and also be very useful for a personal project i’m interested in which I design my own model plane.