Week 5

This week I learned how to use the lathe. This is because I was waiting on parts to arrive, which they now have, in perfect timing so I can start the next phase of the float. So in this little down time in the float project I decided to do this as I will also need it later on in the project, to turn the aluminum piston.

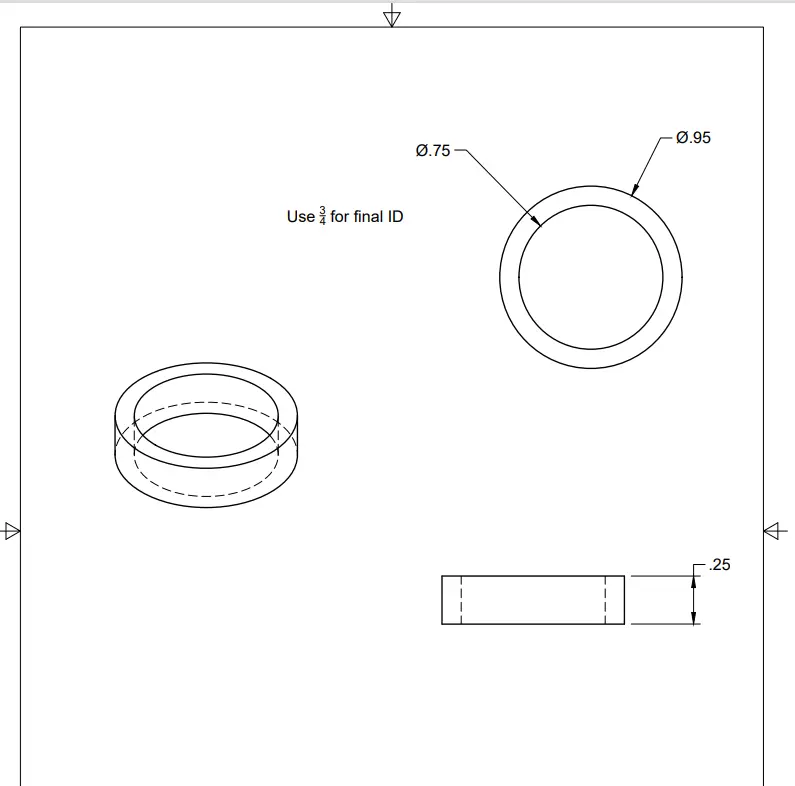

I started this project by quickly and simply modeling the ring in CAD, and then printing out a drawing of the part that would be used in the machining phase.

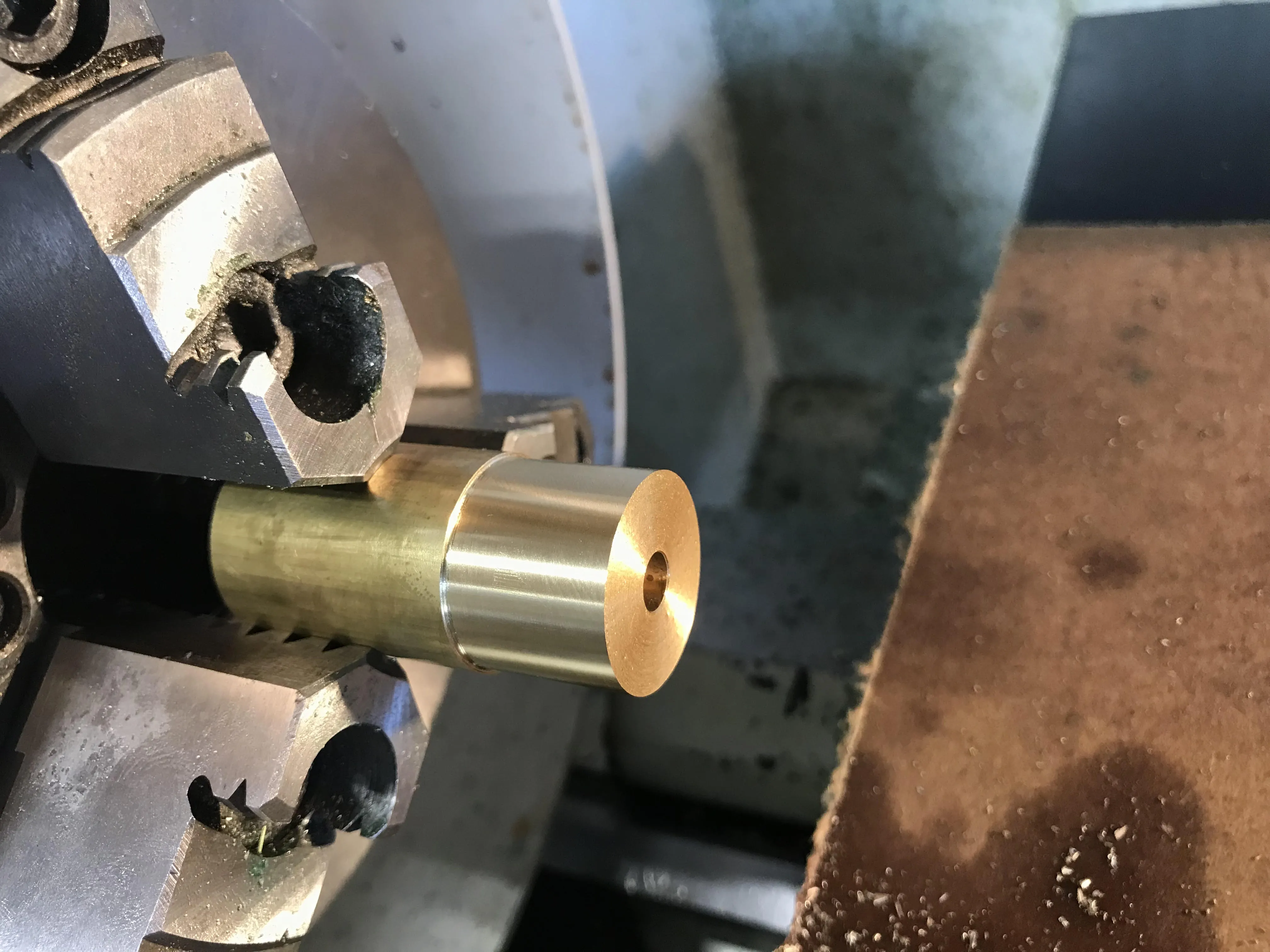

The next step was then to cut and prepare the stock, which I did cutting a 2 inch long peice from some 1" brass round. Next I put it in the chuck and got ready for the turning operations. The first thing that I did was face the end of it, so that it was smooth. There was no real dimension to this as all we needed was a flat plane to measure from later. Then, I turned the outer diameter, to 0.95". I was very happy with the finish and also the fact that I hit it to within 2 ten thousands, ending up at 0.9502" in diameter, which is very accurate. The next opperation was the longest, as we had to incrementally bore out the inner diameter of the ring. We started with the center drill, and then worked our way every 1/8" up from 1/4" to 3/4". Unfortunatly we had to use drill bits as the hole is too small for boring bar, because drill bits are not very accurate in terms of the diameter of the holes they cut. Thus I used a telescoping gauge and a micrometer to check the diameter, and it turns out that I got lucky, and it is 8 ten thousands over the specified dimention. The last operation was to part the peice, which I did in two steps stopping in the middle to file the outside edges, giving them a more uniform champfer, and also deburring it. After, I cut all the way through, I was then able to deburr the ring, and clean up.

The ring project is pretty fun, and definitly a good beginner project, I now, definitly have a much better idea of what I am doing and will be much more prepared when I go to turn that 4" aluminum stock later this fall (hopefully).