Week 4

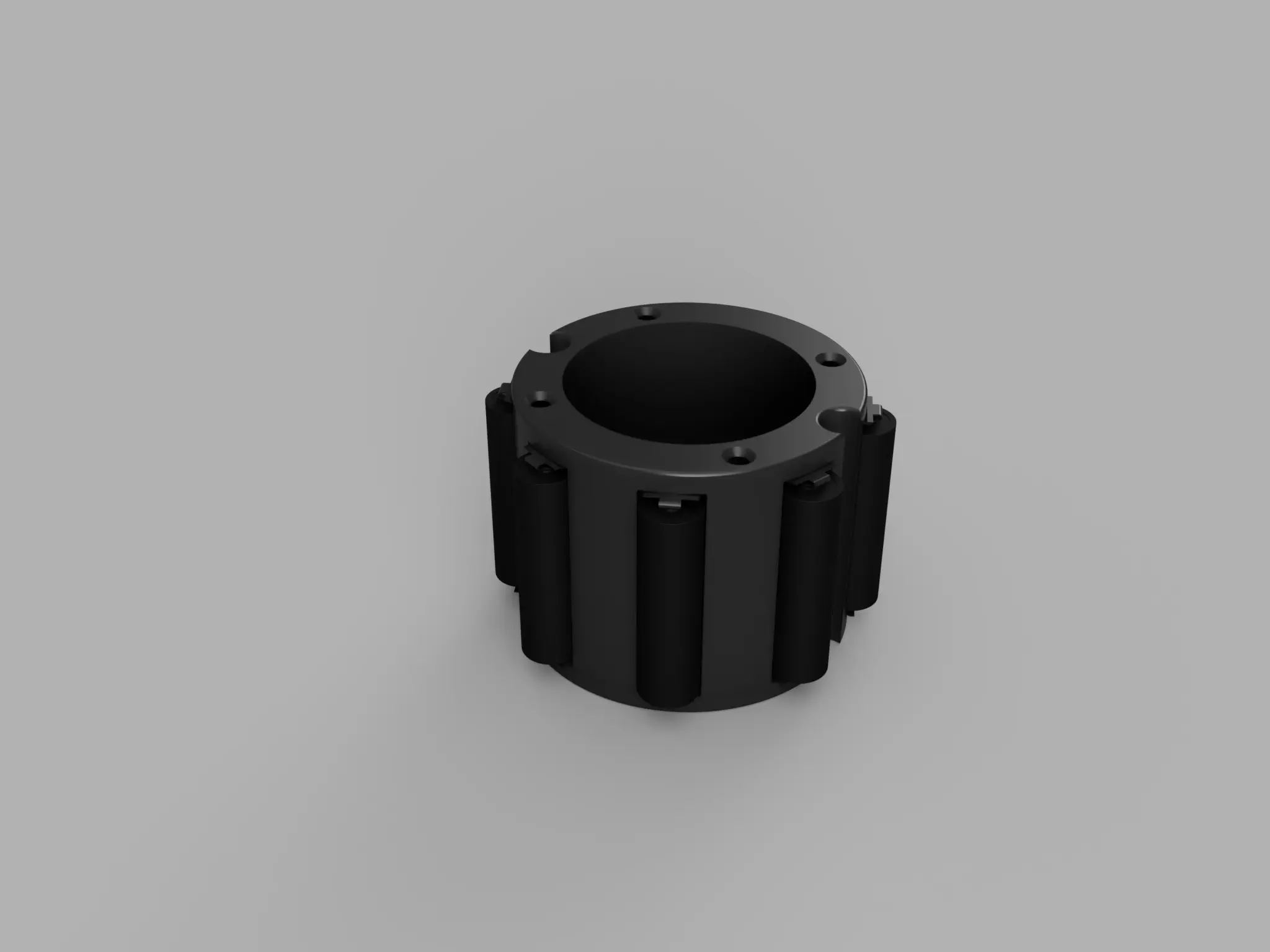

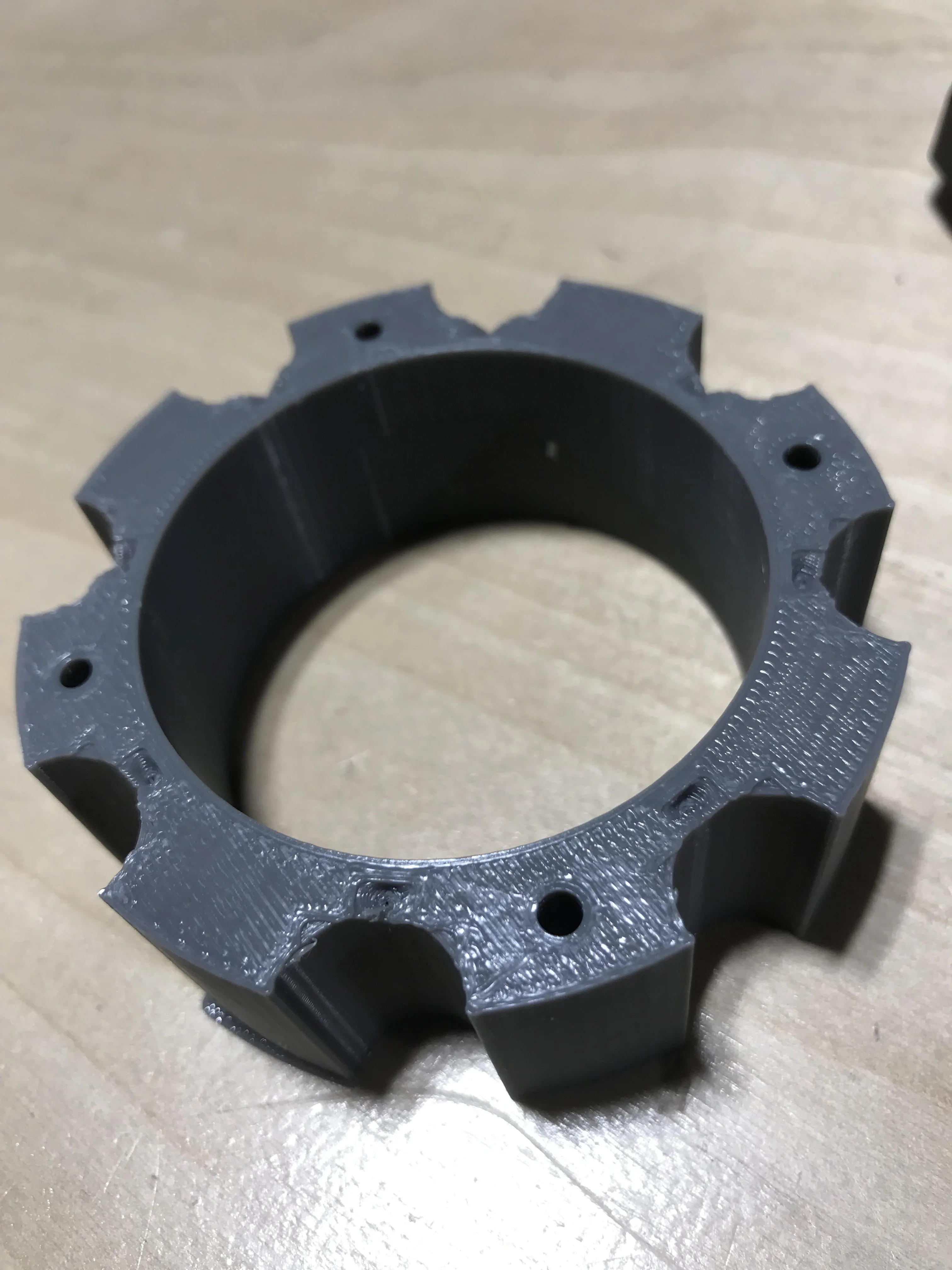

With our nice four day week, I continued to design the intricate systems on the float, with the main focus on the Battery Holder. This brick of plastic is designed to hold 8 AA batteries. Last year we used off the shelf battery holders, which were nice and easy, especially since we were in a time crunch, however they were not very space effecient. This year we are going a different route. We ordered some battery contact/clip thingys from Digikey, and are custom manufacturing our own battery revolver. While not dangerous, this holder is much more space efficient and also much cooler than our previous design. That being said it is muuuuch more complex. It took me about a day to fully model it, with someone else taking a crack at it before me.

The battery holder works like a normal battery holder. The main body holds the clips which will be soldered, then epoxied in place (I would have preffered screws, but there wasn’t much space). There is then 2 plates on the top and bottom that do double duty of reinforcing clips, and hiding/protecting the wires. These are then held in with countersunk screws (for the sleek flush finish). To make these screws work I tried both tapping the resin test peice, and using threaded inserts to no avail. Unfotunatly the one strongish method I found was essentially using the screw as the tap and forcing it into the hole which I don’t love, but i’m ok with it as it isn’t a critical part and there are multiple screws. The two circle cutouts on the side are to allow for clearance for the anti-rotation rods that have been the subject of too many blog posts already.

In other news the 3d Printers, simultaneously completed prints unattended, after school yesterday, so hopefully they are fully operational again.

So far the float is doing very well, and we have met/exceeded our september goals. You can find the overall project outline on my partners website, Scott Campbell.