Week 3

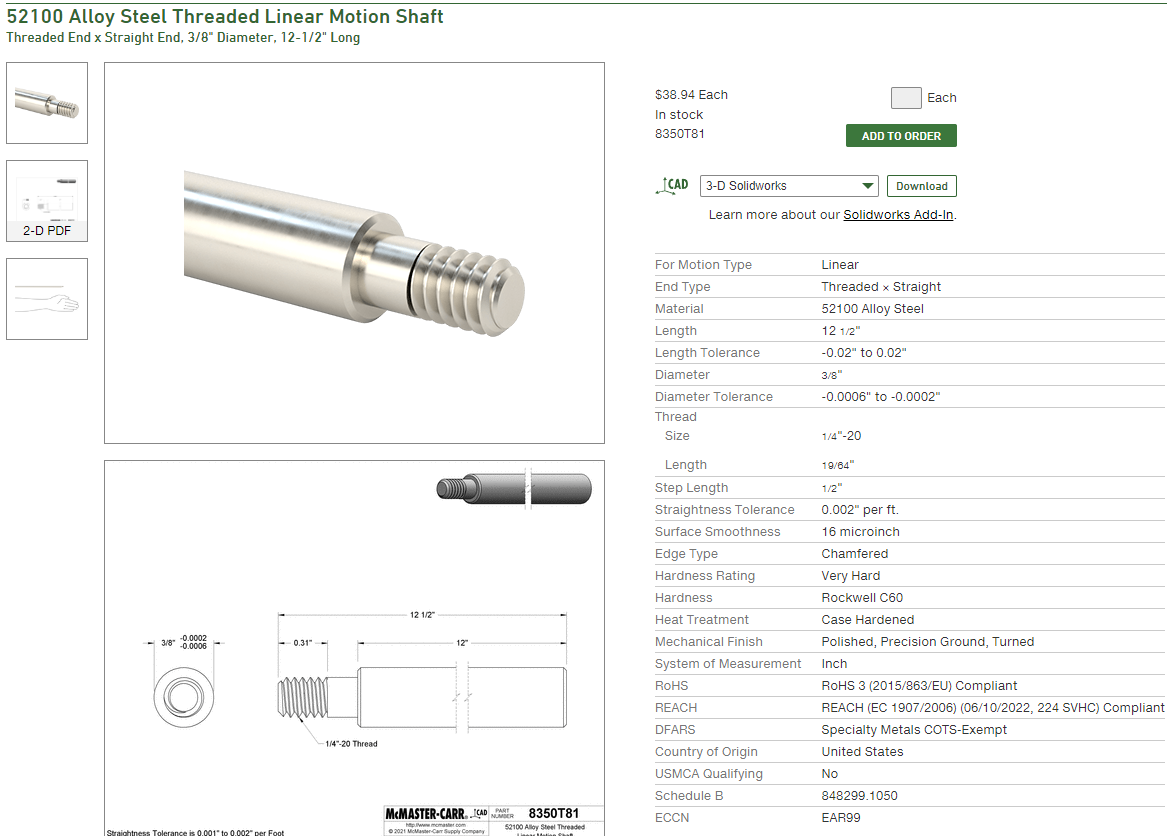

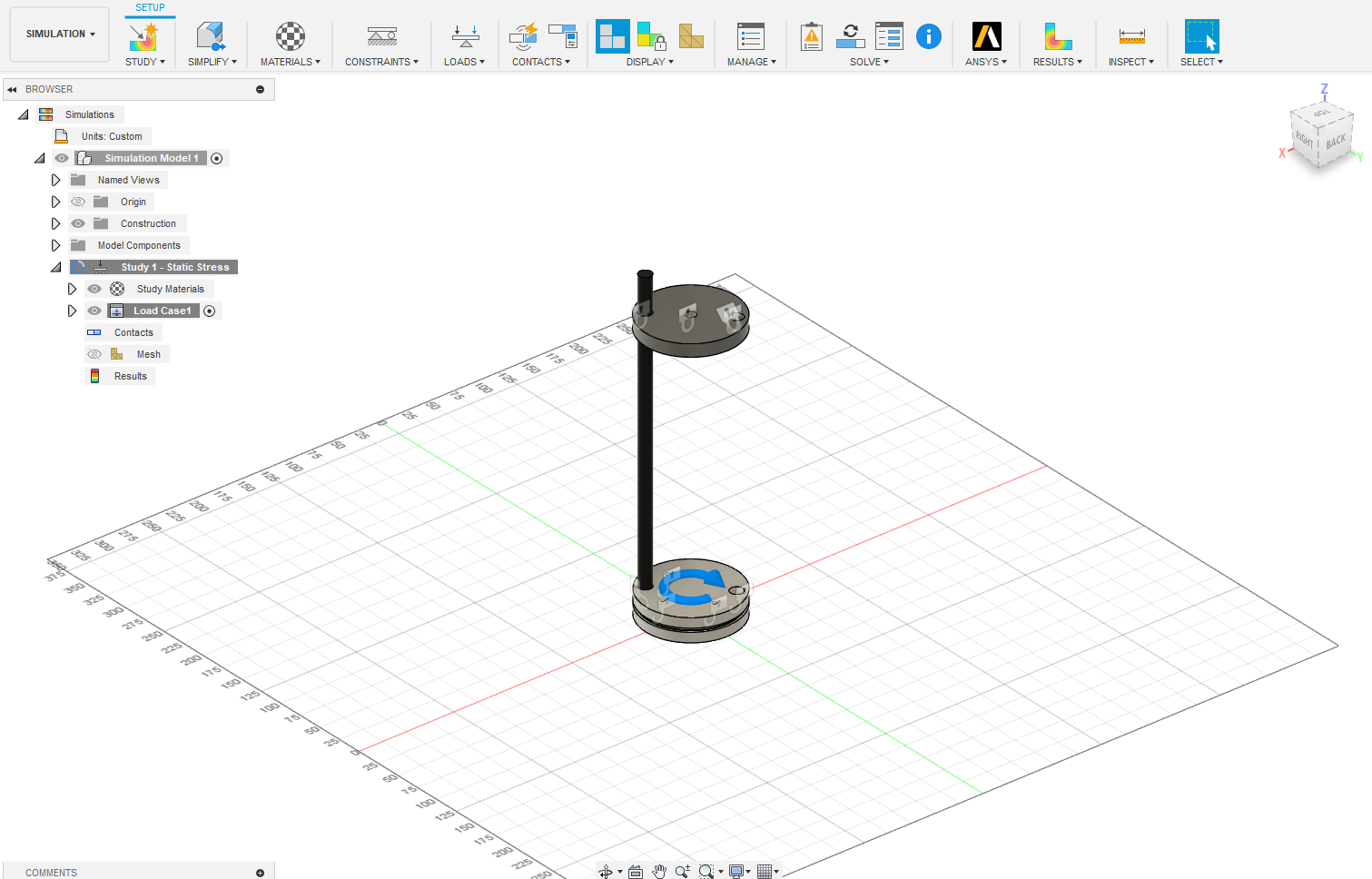

This week I fully focused on the float, and particulary the anti rotation rods. I have been trying to figue out what material to use for them fou a couple weeks now, but this is the first week where I have made it a goal, and not an overarching requirement. This is much easier said than done. Last week we diecided that it wasn’t worth the time and effort to use piping to hide the wires, which is a bit sad, but also makes my life so much easier. Originally we were going to use Delrin, which is a machining plastic that is also fairly cheap. I, however, wasn’t entirely sure how rigid it would be, so i decided to try to do the math. Now this was hard. I had an incomplete, and oversimplified idea of how to do this. Because of this, I then decided to try out using fusion 360’s simulation software which didn’t go to plan aswell. Because of this I decided instead to try to do the math again, which I got much further in. However this is when I realized it would be a whole lot easier to just order a steel precision ground rod that I know will withstand the force of any motor we throw at it.

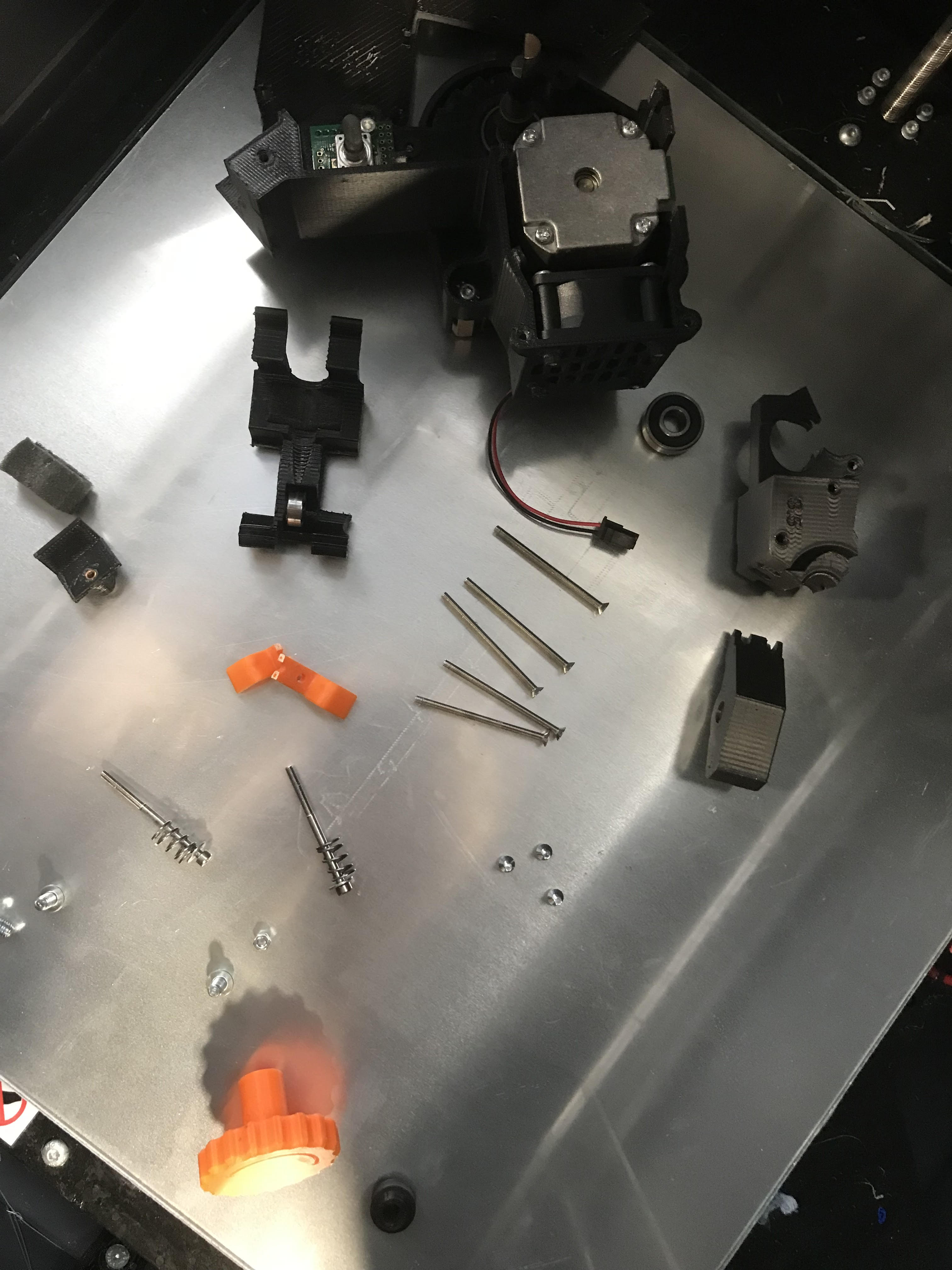

The simulations take a lot of time due to their complexity and sheer amount of math, due to this I was able to do a small little project for the shop. The 2 Fusion3 410 printers the shop has, in my experience has always been an on going project to get printing properly, if at all. This week I fully took apart one of the extruders, in order to fix a filament feed error that we have been getting for a while now. In this process I also ended up breaking a part, but fortunatly it was 3d printed from the factory and I was able to find the .stl file easily enough and replace it by printing it on the other 3d printer. This seemed to fix the filament feed error, but It did malfunction on the benchie I printed afterwards, although that problem was an easy fix