Week 27

This week was mainly fixing mistakes that were made last week, and last year. Last week the magnet holders decided to be a little goofy and set us back about a week, so i decided they needed a redesign.

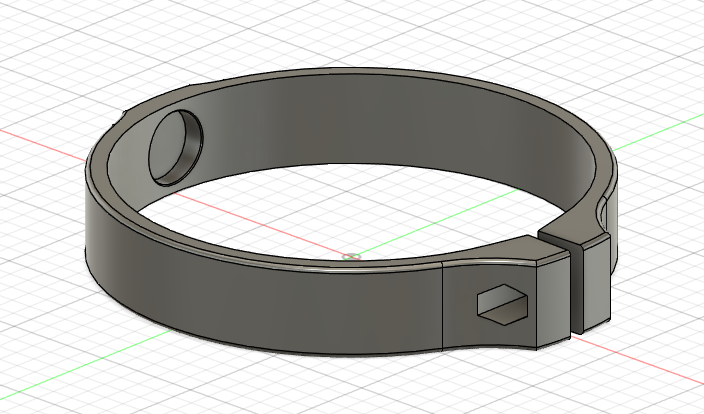

Instead of using the threaded inserts and set screws, I decided to use a clamping mechanism, and a captured nut. This will aleviate thesignle point of stress on the tube, and give us a much more even clamping force. Hopefully this will be less destructive, and also less annoying to construct.

So as it turns out, my cad model was very wrong. In the CAD model I had the tube at 18" but in reality we had decided on 24" a while ago, which is starting to make much more sense now as I didn’t have to do many of the things that I thought I was going to have to do. I fixed this, as well as making a new tube which should work much better than the one with a gaping hole in it.