Week 16

This week was quite productive for such a short week. I had two main projects, the battery holder, and the motor holder. Both of these were things that I already had done the design work for, I just now needed to print everything out and bolt it together.

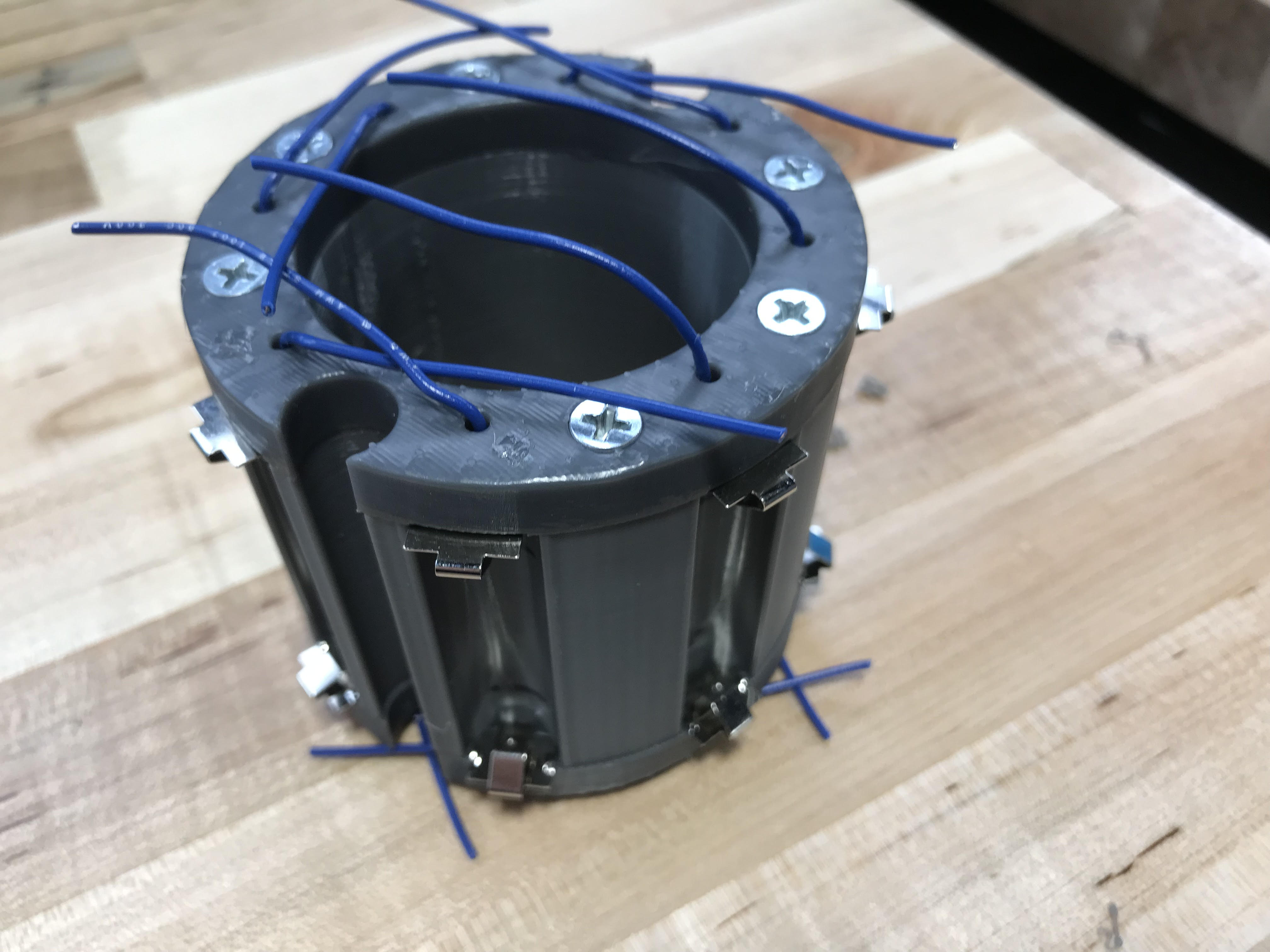

The Battery holder is what I tackled first. I all of this stuff done for about a week, but the main problem was that the 3d printers are incredibly unreliable, and failed 5 times on the print. This being said, I finally got it to work and fot the part. I then put all of the threaded inserts in, and soldered the clips to their leads, and then very carefully assembled everything.

The other thing that I worked on this week was the motor holder. This was very easy. I basically just had to get rid of champfers that I had created at some point as a way to try and print it without support. I decided to just bit the bullet and use a little bit of supports to make my life much easier and the part more reliable. This motor hold just bolts onto the aluminum piston I machined before the vacation.