Week 15

This week I machined the Piston for the float.

The first step was to cut the stock I was going to use, I used about 3.5" of stock, as I needed material to hang on to, and some lee way to approach the final dimensions.

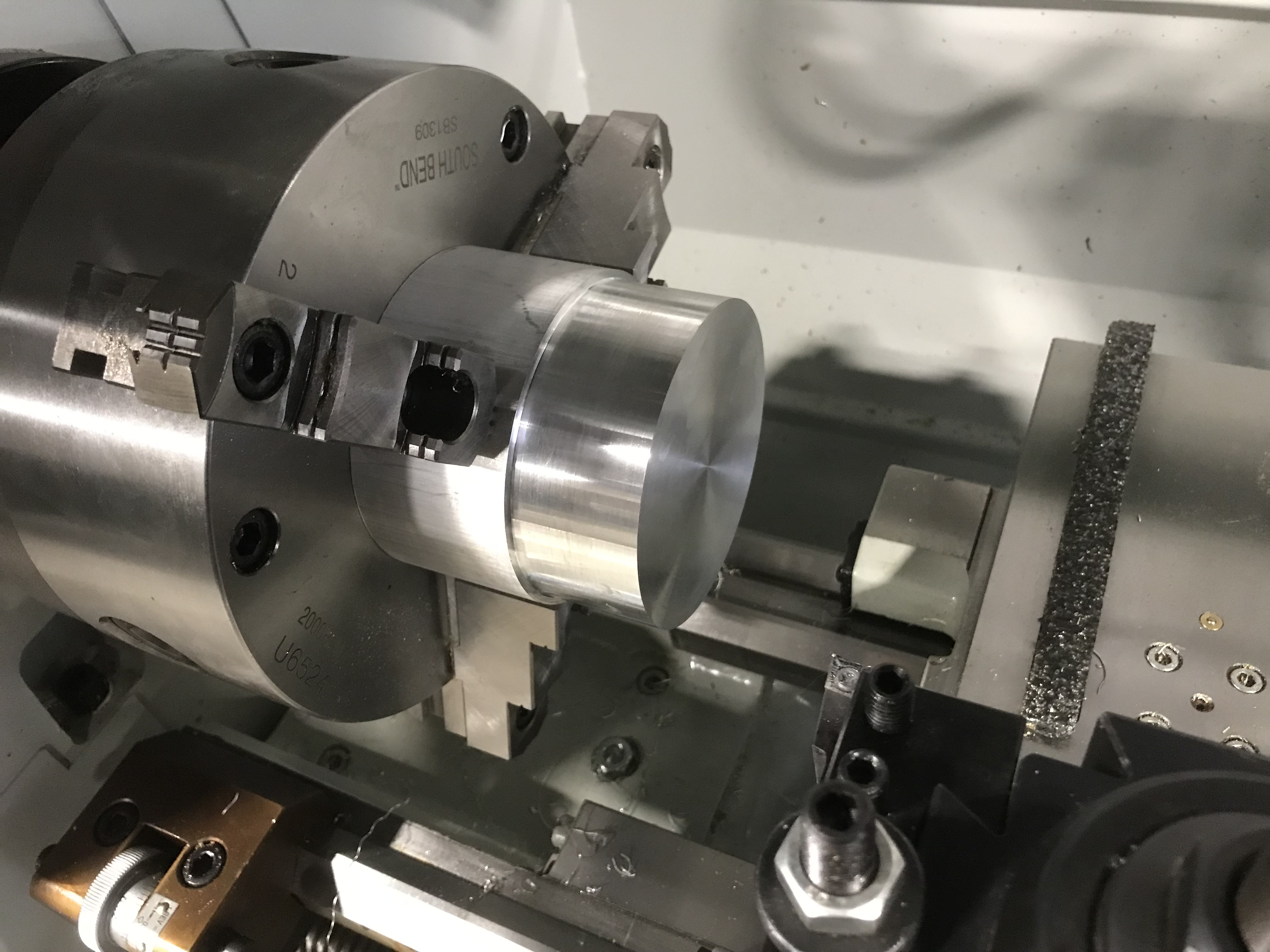

The Next steps were on the lathe. I first faced the front to give myself a good z reference face. Then I faced the outside Diameter to dimension. Unfortunatly I did not have 3-4" micrometers, so I had to use calipers for the dimesions, which was much less accurate.

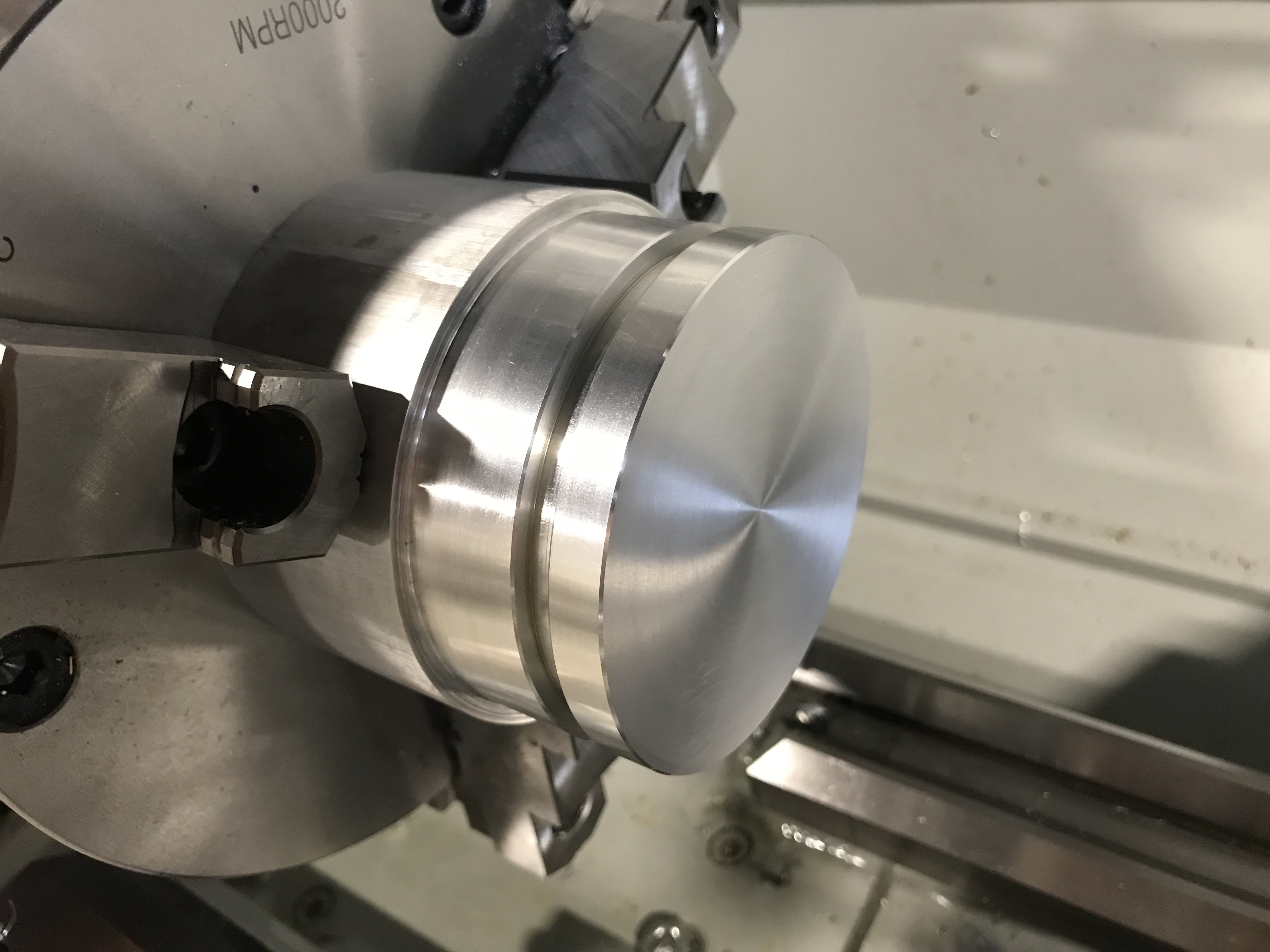

The Next step was to cut the groove for the O-ring. To do this, I used a parting blade, and took two passes, to complete the 1/4" groove. I then took one pass in the middle to clean up the little fin in the middle. I then dropped some nice champfers on the edges.

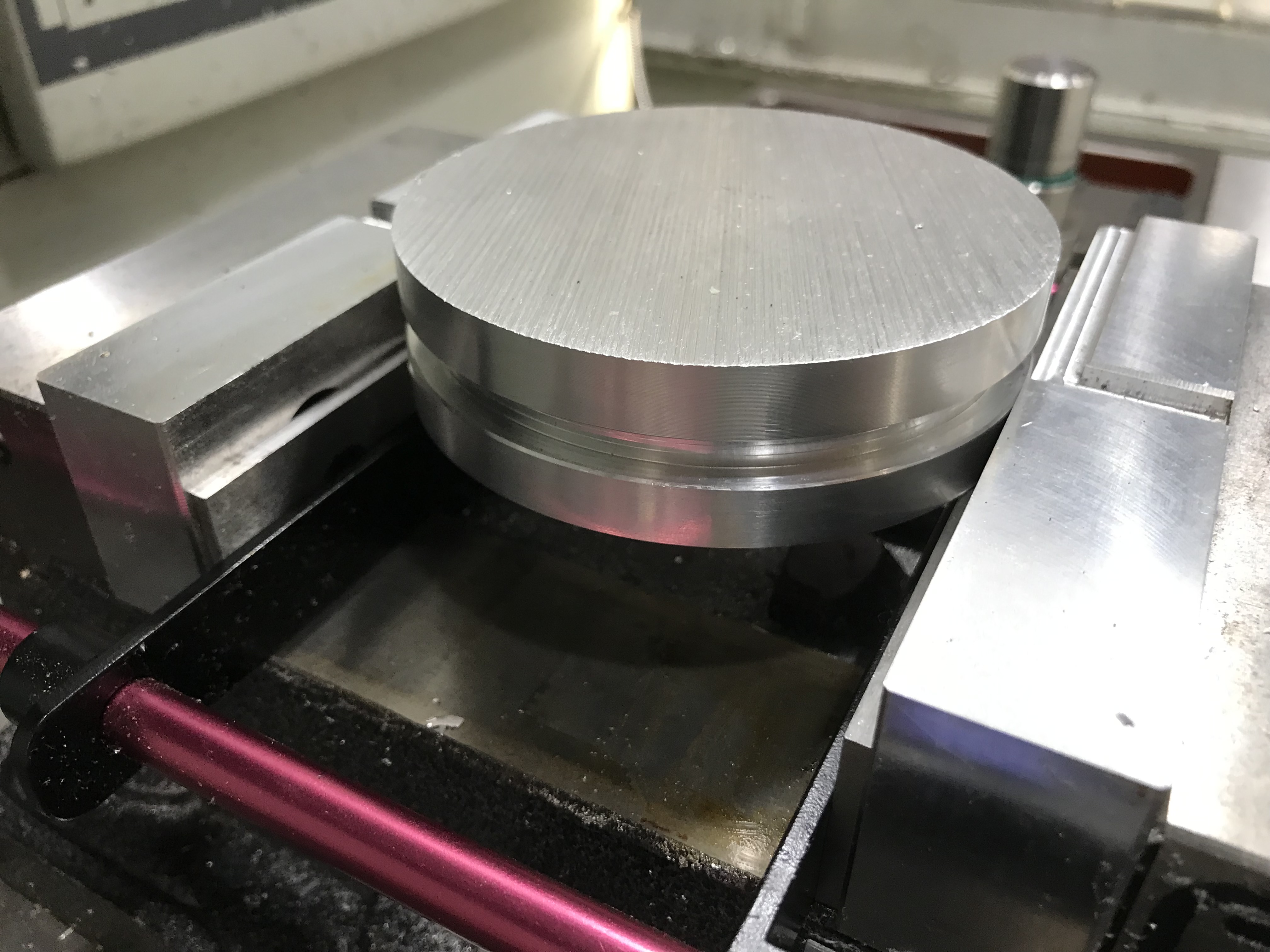

Next I used the horizontal bandsaw to cut the part from the stock, and put it on the mill. This is where I faced it to within 1 thousanth of an inch, and then drilled the holes in it.

I then tapped the holes I drilled with the required threads.

Along side the machining this week, I also continued to work on the battery holder, and it is very close to done, just some of the holes didn’t line up due to the FDM 3d printers being pretty inaccurate.