Senior Week 9

This week we truely got started on the braking on the golf cart. We started off the week getting some numbers on the braking force. This was quite entertaining as it basically entailed us driving the golf cart and slamming on the brake as hard as we can, while there is a bathroom scale on the pedal. From this I gathered that I would really prioritize speed of the actuator over force. This being said I also gathered that I definitly needed a minimum actuator force somewhere between 50lbs and 75lbs. After lots of searching for cost effective solutions, I finally found the actuator that I wanted to use.

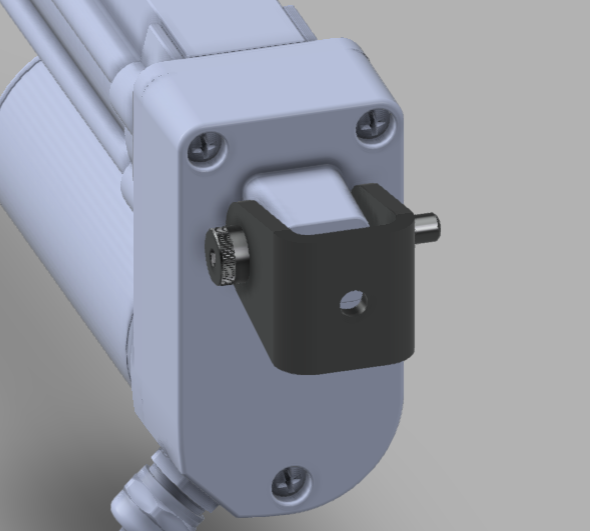

Once I downloaded the 3D model I was able to start making the brackets that will attach the actuator to the pedal and frame. I’m not set on how I want to manufacture these because bending them might be impossible, but milling them might be a bit of a challenge.