Senior Week 5

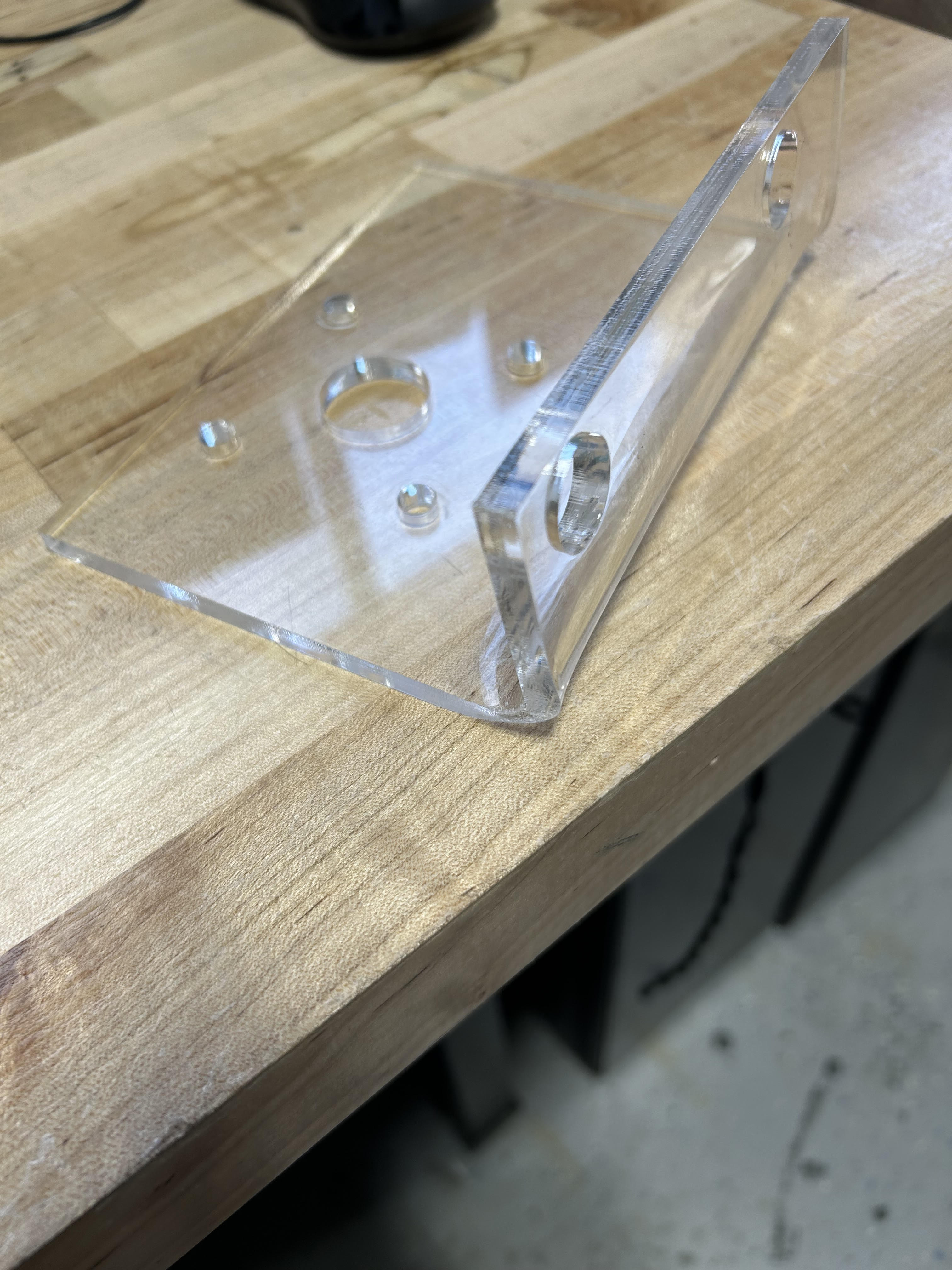

This Week I figured out a few more things on the drivetrain side, like ordering sprockets, and also I bent acrylic. I did this to make a mock up of the motor holder I am going to bend out of steel for the final one. This was also a bit of a strength test, and the bend was able to hold the full weight of the motor, but Id be wary about its ablity to hold it with the motor running and pulling on the steering column.

When the bearings came in I tried to get them seated correctly, however it was nearly impossible for a varity of reasons. because I slitted the thingy to get it over the splines, it was very dimentionally unstable, meaning it didn’t have the right dimesions, to go into the hole, now this would be fine if I had calculated for a smaller amount of an interferance fit. When I put the Bearing in the housing I milled, the shaft didn’t spin, and overall it was bad.