Senior Week 4

This week is when the Pillow block started to really pick up speed. On friday I used the tormach to mill the profile of the pillow block, which was very sucessful for my first time using the cnc funtion of the mill.

after that I now had to remove it from the stock. Now I wanted to just put it on the bandsaw but it didn’t fit in the horizontal one, and the vertical one wouldv’e been really sketchy. So I chucked it up in the manual mill and faced about an inch of material off of it, which took me about a day.

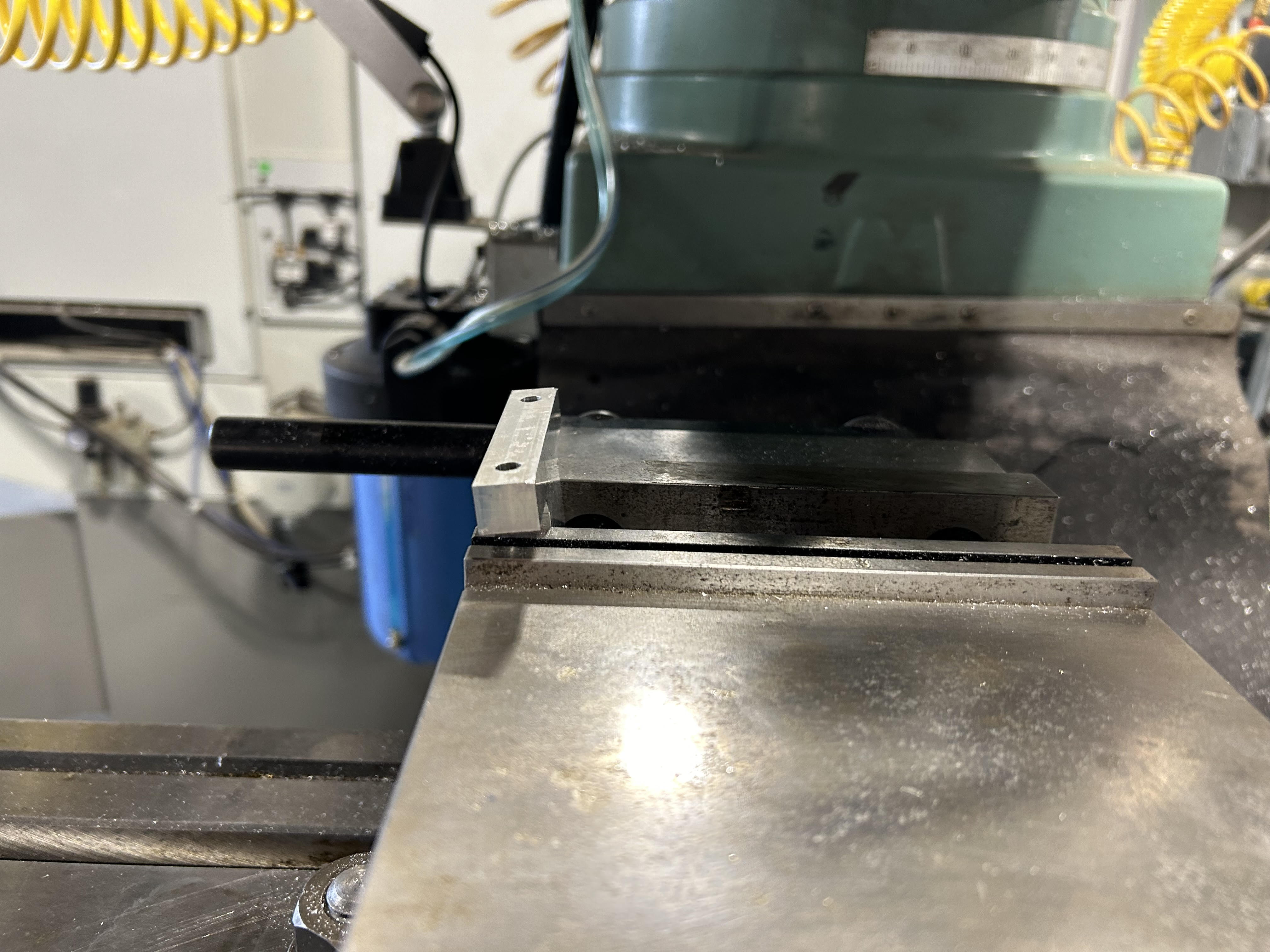

After that What I did was quickly bring it to thickness and then it was time for that pesky angle. I had a few Ideas, and unfortunatly we dont have a sine bar other wise that would be perfect. What I ended up doing is arbitrarily setting it close to where I though 7 degrees was, and then seeing how much it rose as I went along its length, and comparing that with the trig I had done. After that was good I just milled the flat in it and the Part was done.

Now I need to get the bushing, cut a slit into it, and then push it into place while on the steering column, and then screw the part into place, which will definitly be interesting.