Senior Week 30

This week I made the faces for the hammer. I also bored out the hammer handle and plugged it with a cap.

Monday

I started late because I had my AP Calc test that day, and missed 4th period. Starting 5th period, I found an already cut off piece of brass that was just big enough. I then put it in the three jaw and faced it, then turned it down to the right OD. Then I set the distance that the smaller threaded diamter would go to, then faced that down. It turns out that this lathe is really powerful, and can take some insane DOC. I did 50 thou DOC, at .003 inches per revolution. Once I was to diameter, I made a small groove for the runnoff for the single point\ing cutter. After that, it was the end of the day.

Tuesday

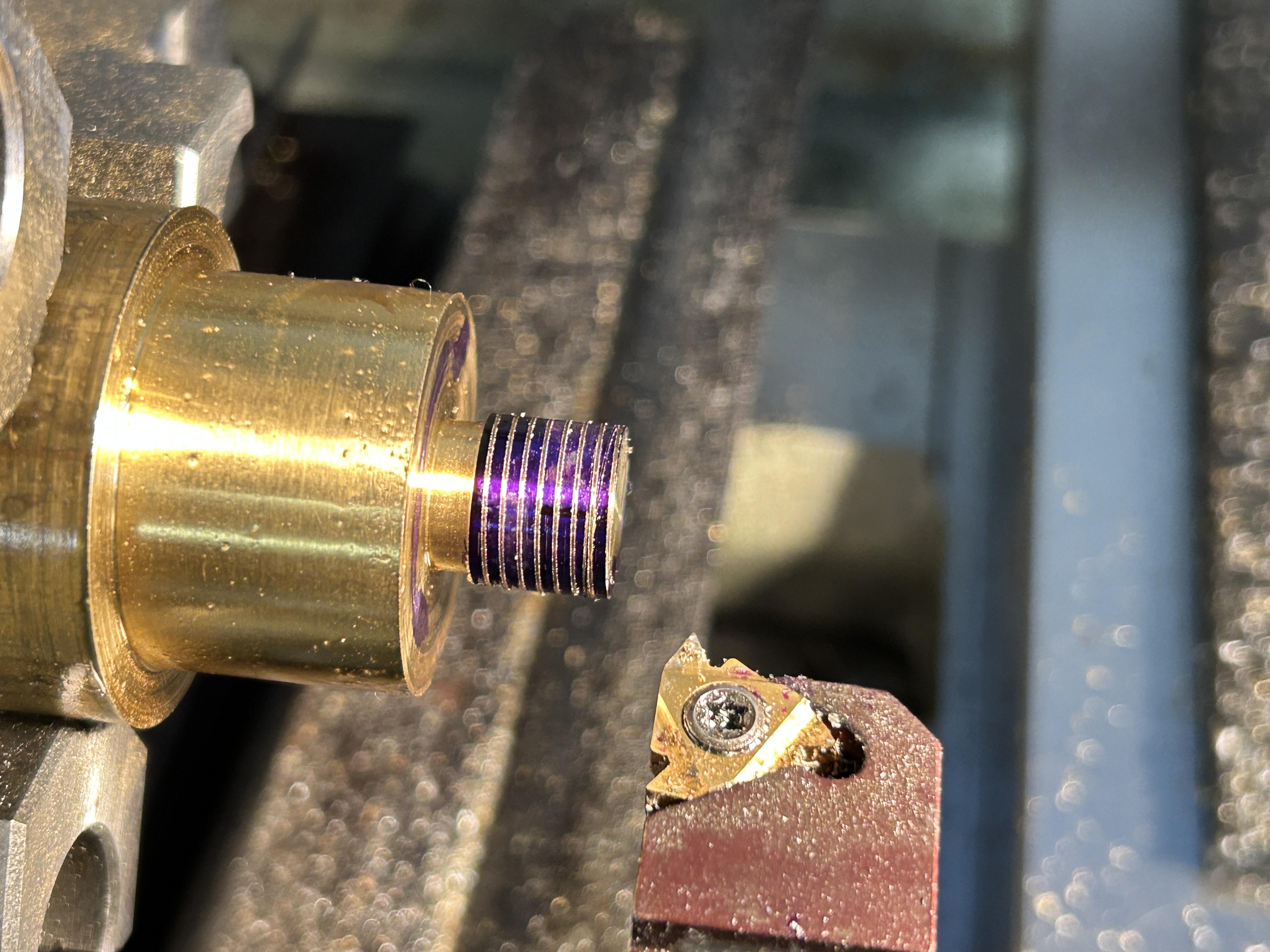

On tuesday, I single pointed the threads. I did this with the guidance of Aaron BenDaniel, who showed me how to do this. It was actually very simple, I had just never done it before. once I got down to depth, it fit perfectly on, but only on one side. I think I just didn’t make it deep enough for the other side. After that, I parted it off, and put it in a collet block to clean up the face, mill the flats and champfer it. After that was done, I decided I would just force it into the other side, and after about 5 mins of doing that it was in and looked good. It was now onto the delrin face

To do this I needed to turn some delrin, but we didn’t have any round delrin stock, meaning I had to make some square stock round. I wasn’t able to do this in a three jaw chuck, so I assembled the 4 jaw chuck that we had never used. It is very large and only needed the camlocks, so I was able to do it fairly simply. Once I had it in the lathe, I needed to indicate square stock into alignment. This needed to be a rough ballpark because the part was a decent bit smaller than the stock, so once I had it within 10 thou on either side I called it a day.

Wednesday

On wednesday, I came up with a somewhat rediculus idea to use a milling insert that takes the ground carbide inserts, in order to turn the delrin nicely. After putting together quite the high speed steel blank puzzle I put the cutter in and started turning. For facing operations It is not very good. The geometry means that the cutter face closest to the face is much lower than the one that is used for turning. This means that I can’t face it completely. Luckily that surface won’t be seen by anyone, and it doesn’t really matter. For turning, it was really nice and performed beautifully. I then switched to a different cutter for the threaded diameter, and got some crazy long chips. I was running the speeds and feeds sort of like titanium, low SFM to avoid heat, and high chipload and DOC beacuse its plastic on carbide. I then signle pointed the threads and it worked pretty well.

I parted off the face, and cleaned it up on the mill, adding the champfers on the flats. I then put it onto the hammer and it fit really well. I then decided that I wanted to bore out a little of the handle, just in order to fix some of the balance issues. I drilled and reamed as far as the 1/4" drill could go, then started on a small brass plug to keep all the dirt and grime out. This would be about a .001" press fit. After a failed attempt I decided that I would come back and try again on thursday

Thursday

I tried a different cutter that worked much better, and after facing everything down, which was very easy because of brass, I was able to tap it in with a hammer, and hopefully I will never get it out.

After that I cleaned up the lathe area, and all the stuff I had been using.

Next week I will be working on centering the lathe tailstock on the spindle axis. This will involve facing big aluminum bars, and turning between centers.