Senior Week 3

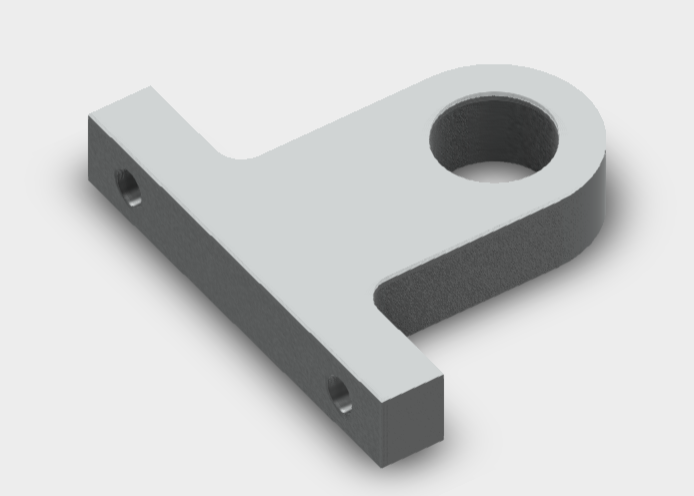

This week I started on the pillow block. Origionally I wanted to just buy one, and slap it in there on the angle and call it a day. The slight issue with this, is that I’m a little bit dumb and thought that all of the ones of the right size dont fit, and thought that It would be easier to just machine my own with a plain bearing. I then realized that the off the shelf one would actually fit. I thought about just using that one, which would be simpler and less effort, but my version would be much more interesting and mechanically simpler. This means its much easier to maintain, and because im not using this for highish RPM its perfectly fine.

Read other posts