Senior Week 2

This week I started the real work on the golf cart, and there are some major updates on the design of the steering subsystem. First of all, Mr. Jackson from metal fabrication came down, and he gave me advice on how to do all of the physical driving parts of the steering, as he has lots of experience with this. He had some really good ideas that I will definitly be using.

The first major change is the switch to chain drive from belt drive, as we were definitly running into some cost issues with belt drive. The other change is the addition of a pillow block right next to the sprocket. This will allow the forces of the steering motor, to be absorbed in something that is designed to take the load, unlike the bearings in the steering rack.

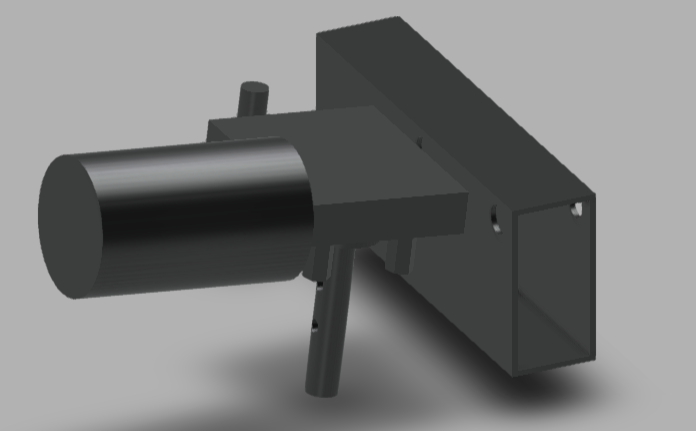

The next thing that I had to do was locate the steering column in reference to the aluminum tube, this probably took me two hours, of finding different ways of measuring the angle and distance, that are more and more accurate, while also running back and forth from the computer to the cart. This was very painful, but also very necesary. Once I got that done, I was able to modle the motor pretty easily, just a small amount of creativity needed. Now Im able to model the motormount using the sheet metal tab in fusion.