Senior Week 16

This was our first full week back from winter break. Now that we are back, I am starting on the manufacturing of the stage motorization components. This week I was able to get the trolley completely manufactured, however not without issue.

Starting off, we tried using the 4th axis to machine this part, however we repeatedly ran into an issue where the z wasn’t centered on the part, when the axis rotates. When the 4th axis rotated to machine the other side, those features never were accurate to the other side in the z direction. This wouldn’t work as the features that allow it to slide are milled on the two different orientations. This took 1 day out of this week, but all of the two day week before.

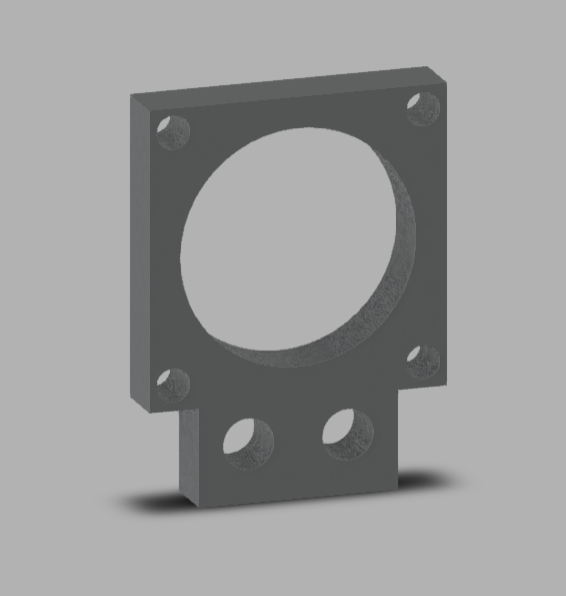

Now I have started to machine the motor plate for the x axis. This is a part I am going to machine fully manually, both for its simplicity, as well as for the practice.